Description

Monitor and Control of Greenhouse Environment System Using 8051

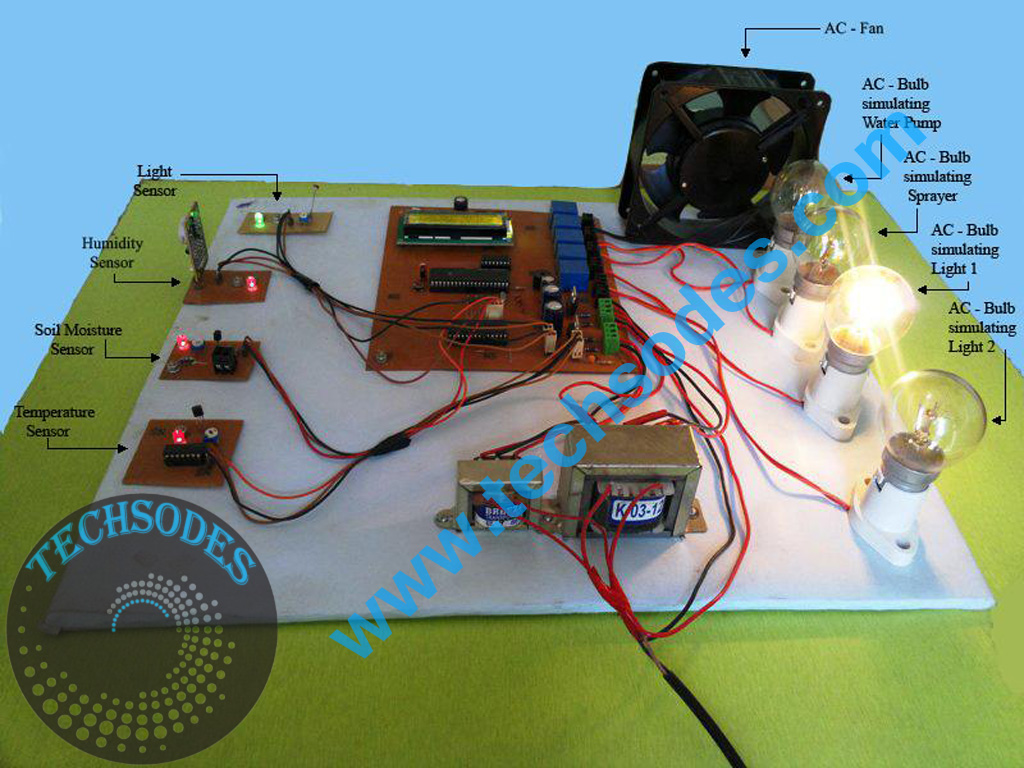

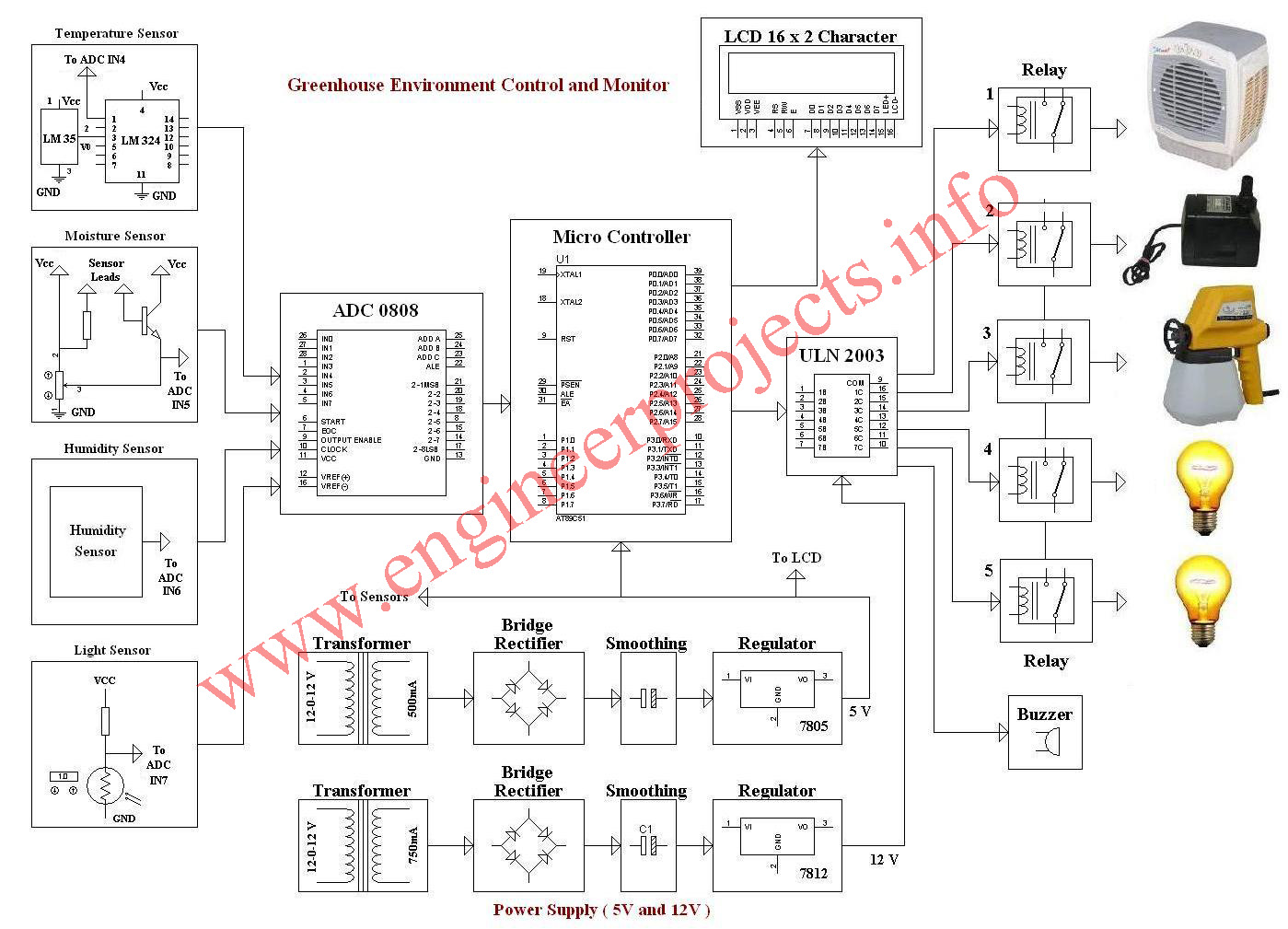

The “Monitor and Control of Greenhouse Environment System Using 8051” is an embedded system project designed to monitor and regulate the environment inside a greenhouse, optimizing conditions for plant growth. This project involves a combination of sensors, controllers, and actuators, all interfaced with the 8051 microcontroller to automate processes like temperature control, humidity control, and soil moisture management. The use of various components such as the LM35 temperature sensor, HR202 humidity sensor, soil sensor, LDR, ADC0808 analog-to-digital converter, ULN2003 relay driver, W78E052DDG microcontroller, and various power supply components makes the system versatile and robust.

1. Microcontroller – W78E052DDG

At the heart of the system lies the W78E052DDG, an 8051-based microcontroller. It is the control unit that coordinates the operations of all components, processes data from sensors, and triggers actuators based on the collected data. The W78E052DDG provides essential input/output functionalities to interface with various sensors and actuators, making it an ideal choice for this embedded system project.

The microcontroller processes signals from the LM35 temperature sensor, HR202 humidity sensor, LDR (Light Dependent Resistor), and the soil moisture sensor. It reads the data through an ADC (Analog-to-Digital Converter), processes it, and makes decisions such as turning on fans, heaters, or irrigation systems based on predefined conditions to maintain the optimal environment for plant growth.

2. Sensors for Monitoring the Greenhouse Environment

Several sensors are employed to gather real-time data from the greenhouse and provide inputs to the microcontroller.

- LM35 Temperature Sensor: The LM35 is used to measure the temperature inside the greenhouse. It provides an analog output that is proportional to the temperature in Celsius. The microcontroller reads this value through an ADC, and based on the temperature value, it can trigger heating or cooling systems to maintain the desired temperature range for plants.

- HR202 Humidity Sensor: The HR202 is a humidity sensor that measures the relative humidity inside the greenhouse. This sensor works on the principle of resistance variation due to humidity changes. By monitoring the humidity level, the system can control devices like humidifiers or fans to maintain the ideal humidity levels for plant growth.

- Soil Moisture Sensor: The soil moisture sensor is used to monitor the moisture level in the soil. If the soil moisture level is below the set threshold, the system can automatically activate the irrigation system to water the plants, ensuring they receive the right amount of water.

- LDR (Light Dependent Resistor): The LDR is used to detect the light intensity in the greenhouse. This sensor helps regulate the opening and closing of ventilation windows or shades based on the light levels. If the light intensity exceeds a certain threshold, the system can trigger fans or shade systems to protect the plants from excessive heat.

3. ADC0808 Analog-to-Digital Converter

The ADC0808 is an essential component in this system for converting the analog signals from sensors like the LM35, HR202, and soil sensor into digital data that the microcontroller can process. The 8-bit ADC0808 provides 8 channels, which means it can accept multiple sensor inputs simultaneously, making it an ideal choice for this system where multiple environmental factors are being monitored.

4. Actuators and Control

Once the sensors provide data, the microcontroller processes this information and takes control actions by activating actuators. These actuators are typically controlled through a relay driver circuit, which enables high-power devices to be switched on or off based on the processed data.

- ULN2003 Relay Driver: The ULN2003 is a high-voltage, high-current relay driver IC that interfaces between the microcontroller and relays. It is used to drive 12V relays that control high-power devices like motors, fans, or water pumps for irrigation. The relay driver ensures that the microcontroller’s low-power logic signals can control high-power devices safely.

- 12V Relays: These relays are responsible for switching the connected devices, such as a fan, heater, or water pump, based on the microcontroller’s decisions. They are triggered by the ULN2003 and help maintain the optimal conditions in the greenhouse.

5. Power Supply and Voltage Regulation

The system requires different voltage levels to power various components like sensors, the microcontroller, and actuators. To ensure the proper voltage levels, multiple power supplies are used.

- 12-0-12/500mA Transformer: This transformer steps down the AC voltage to the required lower voltage for the system’s circuitry. It provides dual 12V outputs, ensuring that the actuators like relays and fans receive the required voltage.

- 7805 Voltage Regulator: The 7805 is used to step down the 12V DC to a stable 5V DC to power the microcontroller and low-power components such as the sensors.

- 7812 Voltage Regulator: The 7812 is used to regulate the 12V supply to ensure that all high-power components like the relay drivers and fans receive the correct voltage.

- Bridge Rectifier: The bridge rectifier converts the AC voltage from the transformer into DC voltage, ensuring a stable power supply for the entire system.

6. System Operation

The system constantly monitors the greenhouse environment by gathering data from the temperature, humidity, soil moisture, and light intensity sensors. Based on the input, the microcontroller decides whether to activate heating, cooling, irrigation, or shading systems to maintain optimal growing conditions. The microcontroller can be programmed with different thresholds for each parameter, and when these thresholds are crossed, the system will automatically trigger the appropriate actions. For example, if the soil moisture level is low, the system will activate the irrigation pump; if the temperature is too high, the fans will be switched on.

7. Conclusion

The “Monitor and Control of Greenhouse Environment System Using 8051” is an effective and efficient solution for automating greenhouse operations. By using a combination of sensors, a powerful microcontroller, and actuators, the system can monitor various environmental parameters and take necessary actions to maintain the ideal conditions for plant growth. The inclusion of components such as the LM35, HR202, soil sensor, LDR, ADC0808, ULN2003, W78E052DDG, relays, and voltage regulators ensures that the system is both reliable and cost-effective for real-world agricultural applications.

Reviews

There are no reviews yet.